Lachie Craw, Contract Milker at Southern Farms’ The Narrows in Riverton, packs quite a bit of farming experience into his youthful frame. He grew up on a sheep and beef farm just out of Waikoikoi in west Otago, worked weekends dairy farming before going full time for family friends, a year dairy farming in Ireland and the same again in Australia, a stint at Farm Source and then the past five years at The Narrows.

In this article, we hear from Lachie as he talks about his time at The Narrows, his farming ethos, the progress he has made over the past five years towards improved land management practices and where to from here.

Taking the right approach

Lachie is driven to work smarter, not harder. As he says “I’m all for working hard. But, you know, there’s got to be a balance between work and family life and I look to incorporate that approach with my workers. Flexibility is key. The farm owner just wants to do things once and do it properly, which I’m definitely happy about”. Lachie has good stability in his crew of three full timers, including himself, and a couple of part time calving helpers. This year he has been able to drop one full time staff while maintaining production, without increasing work effort. So things are definitely heading in the right direction.

The Narrows

The Narrows is part of the Southern Farms Ltd group, nestled between the Pourakino and Aparima rivers across from Riverton in Southland. Lachie explains “We’re about 290 hectares effective. This calving we’re going to calve down to about 880, peak milk 850. When I first got here, we were 950 peak milk. The idea going forward for us is milk less cows and do the same production or more, essentially. The last couple of years they’ve averaged around that 460kg milk solids per cow. The year before I got here it was 330kg so we’ve come a long way.”

For Lachie, it is all about setting The Narrows platform up to farm sustainably in the long term. As he says “100 to 120 less cows and be able to do the same amount of production you know, there’s cost savings in that because you’re not running the shed for probably an extra half an hour a day. And it takes the pressure off time and labour”.

When you couple this with improved pasture management and an improving herd quality, it’s a win-win.

Five years ago

Lachie spoke of some initial observations when he first arrived at The Narrows. The clover root weevil was a major problem. If you drove around the farm and you’d be lucky to find two clover plants. You might have found one worm.

“I think the practices I was coming into were probably non-existent, to be fair. I remember when we when first came and had a look around the farm prior to moving here. We drove past a couple young grass paddocks that the cows had just come out of after a storm. And the paddocks were black. Practices and management just wasn’t where it needed to be.”

Lachie continues “You’d put a mob in a paddock at five o’clock in the morning, you go past them a few hours later at nine o’clock and they’re just not happy. They’ve trampled half the paddock and want to get out, even on a fine day”

Back then The Narrows were wintering about 300 cows on farm on fodder beet. There was plenty of it but the problem was that the fences were only being moved about half a metre to a metre per day. Lachie explains “If you’ve got a five or six hundred kilo animal staying in one place, that just ruins the soil structure. You might have grown 30 tonne that year, but you’re only growing 8 tonne for the next five years. So it just doesn’t stack up.”

A step change today

There have been many improvements Lachie has overseen at The Narrows and we’ll cover these changes but for now, let’s focus a couple of metrics around grass growth and animal health before we dig into the approach Lachie took to get here.

Dry Matter

Last year Lachie grew 14.8 tonne of dry matter on farm per hectare which equated to 720 bales. Three years ago he was making about 180 bales of bailage. As Lachie says “While we’ve got run off blocks, which are run separately around the coast, supplement feed comes from bailage and silage. So with improved pasture management we’ve been able to make a bale of bailage on farm for well under half the price of what you buy one and you’ve got control over quality.” Lachie continues “That bale tends to twice as good as the $110 bail you bought in you know, so, yeah, it’s a no brainer as far as I’m concerned.” Better quality feed at a lower price that positively impacts the bottom line, we like that.

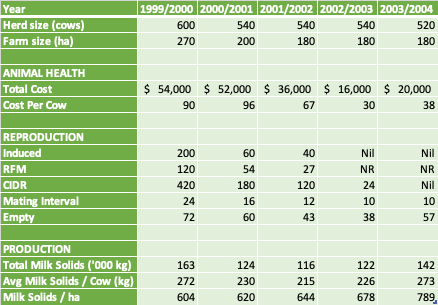

Animal Health

Dairy farmers monitor somatic cells because they can be used as a measure of the health of their cows. Lachie comments “Just the general animal health is a whole lot better. The average cell count the year the year before I got here was around that 360-370 (thousand) mark. First year I was here we were about 300. The last two years we’re at about 170 so we’ve come down a lot”. Great progress there! Lachie continues “You know, there’s no reason why we can’t be around that 120-130 mark. It’s essentially where we’ve sat since Christmas.”

The path to improvement

Like in any business, success is not always a straight line, and there is no end-point – you just keep going. The Japanese have a term for this – they call it Kaizen – which is a compound of two Japanese words that together translate as “good change” or “improvement.” In recent times, Kaizen has come to mean “continuous improvement”.

In a nutshell, the following management practices have helped Lachie continuously improve The Narrows long term sustainability:

- A focus on herd quality that delivers bottom line results with reduced health costs

- A direct drill trial that delivered positive results on yield

- The application of soil aeration to provide oxygen into the topsoil

- The importance of keeping residuals at a decent level (grass grows grass!)

- Applying Fish IT fish hydrolysate as part of the regime to feed the soil biology, boost production and improve animal health through a better pasture diet

- Mixing up grass species to provide diversity

- A continuous programme to regrass old and under-performing paddocks

Direct Drilling

Lachie is a big fan of direct drilling seed into the soil. A couple of winters back he planted 15 hectares of kale. Half direct drilled, half conventionally spread. It was all treated the same over winter. The big win was that Lachie got the half that was direct drilled back into young grass 10 weeks earlier than the conventional.

Improved grasses

Lachie believes it was the overuse of nitrogen that soured the grasses in the early days when he first arrived. Lachie points out “The clover content wasn’t there either. I think that there was so much N on the plant, which probably relied on it, and the palatability probably wasn’t great. It would have soured a whole lot of it. The cows weren’t interested.”

He continues “I definitely think the Fish has helped push things along a bit faster and brought the biology back to life. Before using Fish IT we went round and dug a dozen holes. We were lucky to find five worms total. Today you go and find 10-20 worms in one hole. So the biological activity has definitely come back.”

At The Narrows, Lachie worked out that it was only $3 per hectare more to chopper apply compared with tractor spray boom or Tow and Fert, so one big benefit is that the entire farm is done by lunchtime leaving the afternoon to get back to milking.

Between the supplements in the shed and the improved pasture quality and palatability influenced by the Fish IT biostimulants, the cows are now “happy as” according to Lachie. He continues “It’s the argument of wholefood versus junk food in a way. I suppose if you eat McDonald’s every day then you’re not going to feel great are you?”

Nitrogen Use

Lachie is still using around 160 units of nitrogen over the past couple of seasons. He says “We’re still using relatively high amount of nitrogen. But going forward, you know, the idea is to bring that bring that down” As the biology kicks in and the nutrient cycle gets into full swing “then, you know, there’s no reason why we can’t half what we’re what we’re using. Going forward but we need to get the remaining paddocks renovated first.” We concur, Lachie.

Diversity

Lachie’s grasses are still ryegrass dominant but he has been putting in some clover species, new generation cocksfoot, plantain and rye grass varieties. There are some great benefits to offering diverse species to the biology as the microbe communities in the soil thrive on diversity and give back with a multiplier effect in terms of nutrients to the plant.

Lachie expanded on his views around cocksfoot “They’re pretty hardy plants. I’ve got a paddock of old cocksfoot that I could put 100 cows in today, leave for a week and it’d be black. Two days later it’ll be green again. Based on that I’m including it in the seed mix.”

Residuals

Leaving a decent residual has had a big positive impact on grass growth at the Narrows.

“Two thirds of the year, probably I leave 1600-1650 residual. If I go lower than that, say 1500, it takes a week to recover to 1650 from where it starts growing properly again”. Lachie continues “I’ve been on shorter rounds since I’ve started doing that I think we’ve grown a lot more grass because of it.”

Looking ahead at The Narrows

“Going forward we’ve still got plenty of room to move” Lachie states. “The idea is to keep it pretty simple. Going forward, we are going to renovate a bit more pasture than we have in the past. And just get it to a standard where we can sit at the 10 to 15% a year mark pasture renewal. This will help us grow a lot more feed on farm”

Lachie will stay the path to reduce his units of nitrogen. This will come through a combination of improved natural nitrogen cycling in the soil so that the plant receives synthetic nitrogen as a tool rather than a drug. Applying a liquid N will assist in reducing the amount of units required too. Lachie is taking a good look at the benefits of using a spray application with a Tow and Fert to be able to mix fertiliser, Fish IT biostimulants and other nutrients to get the compounding benefit of a single application of the appropriate recipe of minerals and nutrients.

Lachie concludes “I can see plenty of potential and our aim is to have a cow that’s going to give us 500kg milk solids a year. Some of that’s breeding but a lot of it is management. You know, you can have the best BW and PW cow in the world but if she doesn’t calf or doesn’t produce milk then she’s worth not worth anything. So to get to that level in the next couple of years – that’s the aim”

Good one Lachie, for what it is worth we think you are on the right track. We’ll be sure to check in for an update further down the track.